Corporate Culture

ShanLi attach most importance to "people-oriented, to intellectuals", value a harmonious working and living environment, and only we unite as one, ShanLi will have more explosive force and competitiveness. ShanLi directors and staff are out for "ShanLiman", in the "first and stronger, then do big" spirit of enterprise, to lay a solid basis for internal management, standardized factory production office facilities, strict with employee code of conduct, keep honest attitude, improving the overall quality and stability, focusing on economic growth, achieving profit growth and scale growth in sync, so that make the enterprise eternal develop and eternal operate.

Related Products

More items about molecular sieves

We Have The Best Solutions for Your Business

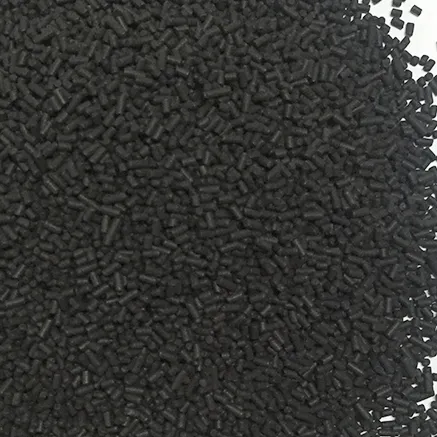

Changxing Shanli Chemical Materials Co.Ltd., is an international modern, outward-oriented comprehensive high-tech enterprise famous for its professional research and manufacturing of international high-end carbon molecular sieve products.

Application fields of 3a molecular sieves

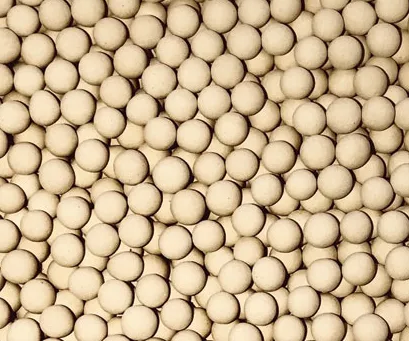

3A molecular sieves, bulk density 680Kg/m³, compressive strength (N) ≧80/P. It is mainly used for the drying of petroleum cracking gas, olefin, gas training field and oil field equipment, and is a desiccant for chemical, pharmaceutical and other industries.

The difference between 3a, 4a and 5a molecular sieves

The difference between 3a, 4a, and 5a molecular sieves are mainly due to the different uses, such as the difference in bulk density and compressive strength.Molecular sieves have 3A/4A/5A/10X/13X and other models, each model has diameters of 0.4-0.8mm, 1-2mm, 1.6-2.5mm, 2-4mm, 3-5mm and 4-6mm. Molecular sieve.

Application areas of 5a molecular sieves

5A molecular sieves, bulk density 680Kg/m³, compressive strength (N) ≧80/P. Mainly used for natural gas drying, desulfurization, carbon dioxide removal, nitrogen and hydrogen separation, production of oxygen, nitrogen and hydrogen, petroleum dewaxing, etc.

User Reviews

What users say about Shanli

Frequently Asked Question

Do you have any question?

The molecular sieves we have now developed has been upgraded on the existing technology, which has greatly improved the product characteristics.

After confirming the order of molecular sieves, we will arrange the packaging here and ship it as quickly as possible.

Our molecular sieves are prepared by the latest PSA method up to 99.999999% at a time, making the production more economical.

Choosing high-quality molecular sieves can improve production efficiency, reduce enterprise costs, and produce more quality products.

Our molecular sieves are produced through continuous innovation and is a professional supplier. The address is in Lvzhou Industrial Zone, Sian Town Changxing, Zhejiang, China.

When you encounter difficulties in the process of using molecular sieves, you can get in touch with our customer service on our official website. Our 24-hour service is online.